|

Primer Effectiveness Study

Completed 5/7/04

5/7/04

Introduction

While working up

loads for my 6mm-250AI, I noticed that I was getting erratic

groups and large standard deviations of velocity with the slower

powders, particularly H4831SC. I had been using CCI BR2

benchrest large rifle primers for my 220 Swift and BR4 benchrest

small rifle primers for my 223AI with good success. However, I

decided to see if changing the primer would make any

quantitative difference.

According to some

sources available on the Internet, the CCI BR2 primers, while

very consistent, are not very hot. My theory was that the slower

burning powders were not getting well lit before the chamber

volume started increasing as the bullet moved down the barrel,

causing erratic burns. According to the same Internet sources,

the Federal Gold Match Large Rifle Magnum primers (215M) are at

the top of the list in terms of heat. Since these were readily

available, I chose these two primers for use in this test.

The Test

For this test, I used

previously necked up and fireformed Norma 22-250 brass, body

sized with a custom Redding body die, and then neck sized with a

custom Lee collet die. The bullet used was a 107 grain Sierra

MatchKing, seated at 2.700” OAL with a 6mm-250AI Redding

Competition seating die. The Redding seating die was reamed out

to 6mm-250AI using the same reamer that chambered the rifle. The

brass, including the primer pockets, was cleaned before the

sizing process after decapping with a universal decapping die.

The test rounds were primed and loaded at the range, as is my

usual procedure for working up loads. Each load was thrown from

a RCBS powder measure previously calibrated with a RCBS 5-0-5

beam scale. The RCBS measure is equipped with the optional

micrometer charge stem.

I instrumented the

barrel of the 6-250AI with a strain gage and a Southwest

Products

PressureTrace data acquisition module.

I used my Oehler 35P to measure the muzzle velocities of every

shot, and entered the resulting velocity data into the

PressureTrace software.

I chose three

different powders for this test across a range of burn rates,

with IMR4895 as the fastest, H4350 as the medium, and H4831SC as

the slowest. All had shown decent results with the BR2 primers,

except for erratic velocities and groups with H4350 and even

more so with H4831SC. All three loads were previously tuned for

best groups, and yielded about the same muzzle velocity. Five

shots for each powder and primer combination were tested.

Results

The results were very

interesting. The 215M primers definitely make a significant

difference with the longer burning powders, particularly the

H4831SC. Note that the PressureTrace data often shows a higher

pressure and slightly delayed trace for the first shot of the

group. While this is considered normal, it is unknown why this

occurs if it is an actual pressure deviation, or if it is a

result of some condition in the electronics. However, when this

does occur, there is no indication of an abnormal pressure or

burn from either the chronograph or the bullet point of impact.

I chose to ignore this anomaly when analyzing these data.

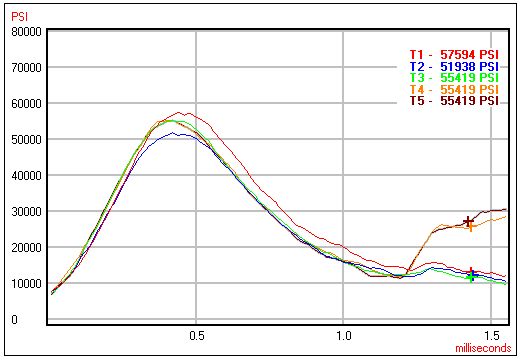

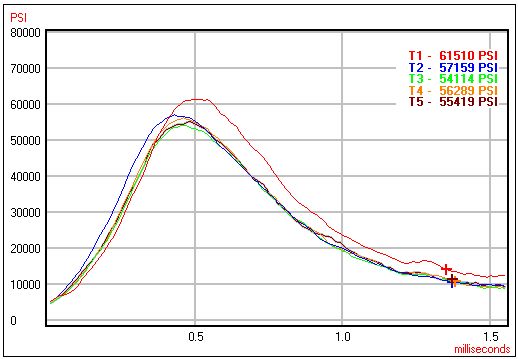

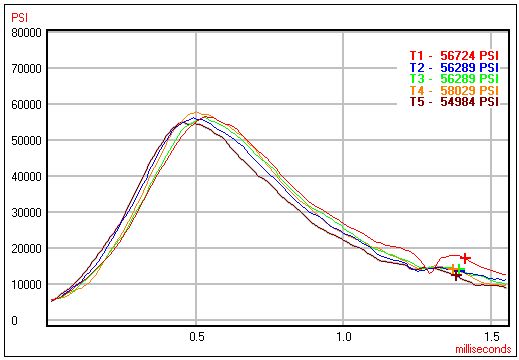

IMR4895 Test Case

Figure

1, Figure 2,

and Table 1

shows plots of chamber pressure from PressureTrace and the

associated statistics for the IMR4895 test loads. In this case

one can see that the pressure curves for the BR2 primers are not

as uniform as with the 215M primers. In particular, the peak

pressures show a significant variation from shot to shot. Of

particular interest is the anomalous secondary pressure event

shown on traces 4 and 5 of the BR2 test case. This is apparently

associated with incompletely lit powder being blown down the

barrel, and then igniting as the pressure drops near the minimum

as the bullet just leaves the muzzle. While the mean velocity

and mean peak pressures did not change significantly, the

velocity and pressure deviations did significantly reduce when

the 215M primers were used. The observed group sizes were

essentially equal.

Figure 1 - 35.0

gr. IMR 4895 with BR2 Primers

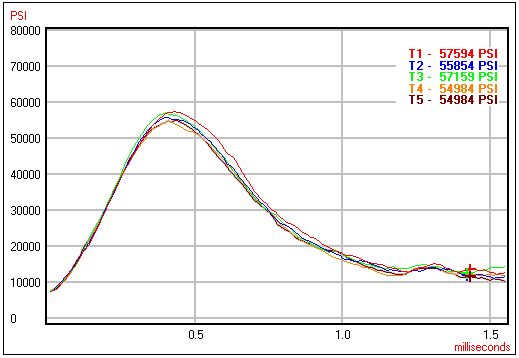

Figure 2 - 35.0

gr. IMR 4895 with 215M Primers

|

Primer |

Powder |

Charge,

gr. |

Bullet |

Mean

Velocity, FPS |

SD

Velocity, FPS |

ES

Velocity, FPS |

Mean

Pressure, PSI |

SD

Pressure PSI |

ES

Pressure, PSI |

|

BR2 |

IMR4895 |

35 |

107 SMK |

2978 |

16 |

45 |

55158 |

2031 |

5655 |

|

215M |

IMR4896 |

35 |

107 SMK |

2988 |

6 |

13 |

56115 |

1214 |

2610 |

Table 1 – IMR4895

Velocity and Pressure Statistics

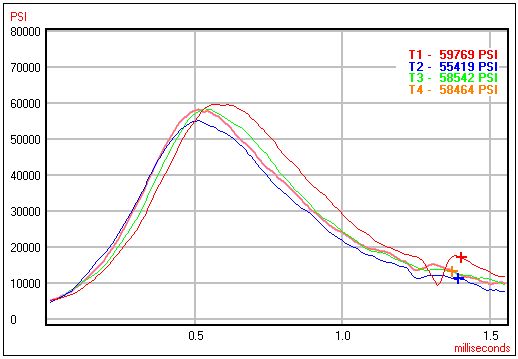

H4350 Test Case

Figure

3, Figure 4,

and Table 2

shows the data for the H4350 test loads. Other than the

previously mentioned “first trace” anomaly, it is again clear

that the 215M primers resulted in a more regular pressure curve,

and slightly higher and tighter velocities. The anomalous

secondary pressure events are missing, as expected with this

longer burn rate powder. The observed group sizes showed that

the BR2 case was slightly better than with the 215M, due to the

higher than desired muzzle velocity of the 215M loads. Please

note that subsequent to this test, when this load was

re-optimized using the 215M, I found that the optimum charge was

actually 39.5 gr H4350. The hotter primer burned the powder more

efficiently, and the one half grain reduction was needed to

place the barrel time at the optimum of 1.257 mS.

Figure 3 - 40.0

gr. H4350 with BR2 Primers

Figure 4 - 40.0

gr. H4350 with 215M Primers

|

Primer |

Powder |

Charge,

gr |

Bullet |

Mean

Velocity, FPS |

SD

Velocity, FPS |

ES

Velocity, FPS |

Mean

Pressure, PSI |

SD

Pressure PSI |

ES

Pressure, PSI |

|

BR2 |

H4350 |

40 |

107 SMK |

3084 |

31 |

69 |

58049 |

1852 |

4350 |

|

215M |

H4350 |

40 |

107 SMK |

3112 |

25 |

62 |

56898 |

2812 |

7396 |

Table 2 –H4350

Velocity and Pressure Statistics

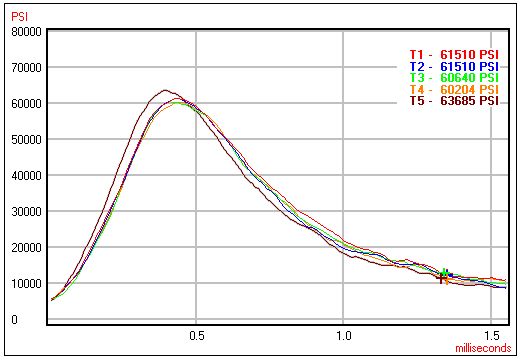

H4831SC Test Case

Figure

5, Figure 6,

and Table 3

shows the data for the H4831SC test loads. As initially

suspected, the use of the hotter primer clearly shows in the

higher peak pressures, higher velocities, and more even pressure

curves. Again, the observed group sizes for the 215M loads were

slightly larger than with the BR2, again due to a higher than

desired muzzle velocity. This load was not re-optimized, since

the charge was fairly compressed, and QuickLoad shows that this

powder did not yield as high a ballistic efficiency as the

H4350.

Figure 5 - 43.5

gr. H4831SC with BR2 Primers

Figure 6 - 43.5

gr. H4831SC with 215M Primers

|

Primer |

Powder |

Charge,

gr |

Bullet |

Mean

Velocity, FPS |

SD

Velocity, FPS |

ES

Velocity, FPS |

Mean

Pressure, PSI |

SD

Pressure PSI |

ES

Pressure, PSI |

|

BR2 |

H4831SC |

43.5 |

107 SMK |

3074 |

30 |

83 |

56463 |

1092 |

3045 |

|

215M |

H4831SC |

43.5 |

107 SMK |

3175 |

11 |

30 |

61510 |

1340 |

3480 |

Table 3 – H4831SC

Velocity and Pressure Statistics

Figure

7

through Figure 10

show the velocity and pressure statistics as a function of the

primer type for each test case. The trends discussed in the

individual test summaries can be clearly seen. In particular,

the 215M primers consistently result in higher velocities and

lower velocity deviations than the BR2 primers.

Figure 7 – Mean

Velocity vs. Primer Type

Figure 8 – Standard Deviation of Velocity vs. Primer Type

Figure 9 – Mean Pressure vs. Primer Type

Figure 10 –

Standard Deviation of Pressure vs. Primer Type

Summary

I have concluded that

the use of the Federal Gold Match Large Rifle Magnum primers is

an excellent choice for the 6mm-250 AI cartridges when using

longer burning powders. |